Biosystems Engineering – Research

Research projects in Faculty Biosystems Engineering

(Selection of third-party funded projects of the last 10 years)

Running:

- Strategic Phytocontrol Technologies for the Control of Greenhouse Plants (running)

- Development of a measuring device for the analysis of phytometric reactions on plants (running)

- Feasibility study on powering greenhouses considering volatile power supply and a high proportion of renewable energies (ELGEVOS) (running)

- Practical introduction and optimization of an innovative system for electrolytic water disinfection in greenhouses (SEWIG) (running)

- Development of a plant for the ion-specific control of the nutrition of crops when growing in greenhouses (running)

- Process simulation based on response - Development of a sensor-based intelligent greenhouse management system (PROSIBOR) (running)

- Feasibility Study for Urban Controlled Environment Horticulture in Berlin and Mexico City (UNCOVER) (running)

Completed:

- Development of ion-selective sensors for the continuous acquisition of ion components in circulating nutrient solution supply systems (completed)

- Joint project "Quality Differentiated Grain Harvest" (completed)

- Modelling and Control of Closed Systems in Crop Production Using Artificial Intelligence Methods (completed)

- National joint project "Low Energy Greenhouse Initiative" (ZINEG) (completed)

- ZINEG Live Data Monitor

Leading topic in research in the field of biosystem technology: phytocontrol technology for the control of greenhouse systems

Numerous projects funded by: BLE, Industry, Status: ongoing

Products: prototypes, patent, sensors, control knowledge, software, evaluation methods (Mollier-Analyzer), publications

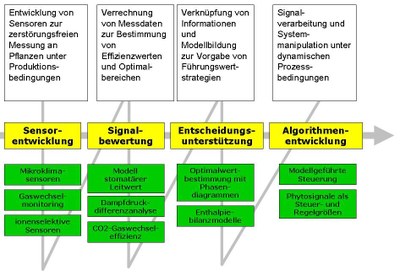

The phytocontrol technology uses phytosignals to control technical processes in the greenhouse. The aim is to optimize the growth process of crops in terms of exploiting the yield potential and achieving desired qualities at defined harvest times. Phytosignals are short-term information on the thermal state, matter and energy exchange as well as growth and quality formation processes of plants, which can be measured non-destructively and online.

Phytosignals can be divided into 3 areas:

Thermo-microclimatic information quantities: tissue temperature of the leaves and fruits, water vapour and partial pressure differences, boundary layer resistances.

Substance and energy exchange: Transpiration mass flows, juice flow rates, [Office1] CO 2 / O 2 gas exchange on plant parts (photosynthesis, respiration), CO 2 / O 2 gas exchange in the rhizosphere, water and nutrient content of the substrate.

Physiological movements and growth-related changes: stomatal conductance, stem length growth , stem cell contractions and fruit diameter increase.

Development of ion-selective sensors for the continuous acquisition of ion components in circulating nutrient solution supply systems

Funded by: BMWi Status: completed

Partner: Fa. Pronova, Berlin

Products: prototype sensor and calibration robot, software, control knowledge, publication

Project objective: Product development for online nutrient solution analysis and production of precisely dosed nutrient solutions using sensors for measuring the ion components in the solution.

As part of an R & D project funded by the PRO INNO II program of the Federal Ministry of Economics and Technology (BMWi), ion-selective sensors for the continuous acquisition of ions in circulating nutrient solution systems were developed. The development took place together with the company iRAS automation GmbH.

Funding: BMBF, Conacyt (Mexico) Status: ongoing

Partner: University of Chapingo, Mexico City

Planned products: tax knowledge, software, publications

Duration: 2012 to 2014

The project was concerned with accumulating tax knowledge for complex closed systems and minimization of input substances and energy for intensive crop production in the greenhouse. With newly developed technology for the bivalent operation of greenhouses as solar energy collectors and plant production facilities, the energy harvest from these plants should be improved, while increasing yields by fixing the enriched CO2 in closed houses and further enriching health promoting components by modulating abiotic growth conditions.

Controlling this complex biosystem technology requires the development and application of new algorithms based on artificial intelligence techniques.

The expertise required for algorithm development was provided by Mexican mathematicians from the University of Chapingo (Mexico City). The software development and integration of these neural networks into the process control software in addition to the system testing was carried out by the Department of Biosystems Engineering of the Humboldt University of Berlin.

National joint project “Low Energy Greenhouse Initiative” (ZINEG)

Funding: BMELV, BMU, Rentenbank and the coordination of the BLE, status: completed

Partners: TU Munich, LU Hannover, ATB, IGZ, LVA Hannover-Ahlem, DLR Rheinpfalz, HS Osnabrück

Products: Prototype, Control Knowledge, Technology, Software, Patents, Publications

Duration: 2009 to 2014

The department developed a collector greenhouse facility as part of a national program aimed at minimizing the use of energy in greenhouse production and reducing the emission of CO2 greenhouse gases.

The aim of the ZINEG joint project was to achieve an ambitious goal: by using all the technologies available to date to reduce heat consumption, greenhouses will be created in which CO 2 -neutral production can be achieved wherever possible.

At the Department of Biosystems Engineering of the Humboldt-Universität zu Berlin the system "Collector Greenhouse" is in continuous development. Through cooling surfaces in the roof space of a closed greenhouse, the excess heat energy is dissipated and stored in a water tank. The aim is to export this stored heat for reuse in other heating systems and reduce the energy footprint of the greenhouse. The closed operation of the greenhouse, the application of low-temperature heat for plant warming, the phytomonitoring developed at HU and the software development for controlling such plants are the ongoing focus of the investigations.

Please visit us on our ZINEG project page!

Development of a measuring device for the analysis of phytometric reactions on plants

Funding: ZIM program of the BMWi, industry,

Status: market launch

Project partner: Pronova Berlin, Steinbeis GmbH Stuttgart

Products: Marketable measuring device, software, system connection to the controller, publications

The project involved the development of a plant culture monitoring system for the permanent collection of plant physiological data such as transpiration, photosynthesis and the measurement of trace gases such as ethylene for the analysis of stress conditions in plant stands. For this purpose, HU-Berlin's experience in the field of water vapour and CO2 gas exchange measurement on plant organs and the know-how available in ProNova with regard to trace gas measurement was used to design a prototype for the combined gas analysis of plants. In cultivation trials in greenhouses, limit values for ethylene emissions are to be determined which can signal biotic and abiotic stress conditions in plants.

ELGEVOS - Feasibility study on powering greenhouses considering volatile power supply and a high proportion of renewable energies

Funding: BLE / Rentenbank, status: ongoing

Project partner: Fraunhofer Institute for Wind Energy and Energy Systems IWES Kassel, Leibniz Institute for Vegetables and Ornamental Plants Großbeeren / Erfurt eV

Products: Feasibility study, simulation software, design knowledge, tax knowledge, publications

Duration: 2015 to 2017

Greenhouse energy concepts are being developed that are geared towards increasing the use of renewable energies and countering the associated volatility. They must be sustainably economical and guarantee stable operating costs of greenhouses. A dynamic energy management strategy takes into account the power supply requirements for optimal crop production. Decisive features of the energy supply concepts are the utilization of overcapacities of power generation from renewable energies for flexible exposure of plant stands and the use of buffer capacities through heat storage in water tanks. A cost-benefit analysis ensures the optimal dimensioning of generation and storage capacities.

SEWIG Implementation and optimization of an innovative system for electrolytic water disinfection in greenhouses

Funding: German Innovation Program DIP-Agrar, BLE

Project partner: newtec-Umwelt GmbH, Rosengut Langerwisch GmbH & Co. KG, Havelia GmbH

Products: Practice equipment, design knowledge, tax knowledge, publications

Duration: 2015 to 2018

Scale-up of the system for electrolytic water disinfection (SeWiG) developed by the Humboldt-Universität zu Berlin and the company newtec Umwelttechnik GmbH on large greenhouse facilities, the technology should be tested, validated and if necessary optimized under practical conditions. This is the prerequisite for successful establishment in horticultural production cultivation. The new electrolytic disinfection system for the treatment of irrigation water is characterized by its functional superiority over the established physical and chemical methods. Further, we want to emphasize is its effectiveness against plant viruses and lower hazard potential for users, plants and the environment.

Development of a plant for the ion-specific control of the nutrition of crops when growing in greenhouses

Funding: ZIM program

Project partner: Leibniz-Institute for Vegetables and Ornamental Plants Großbeeren / Erfurt eV, company Dosatronic GmbH

Products: Plant prototype, control software, design knowledge, tax knowledge, publications

Duration: 2015 to 2018

At present, 30 to 50% of the nutrient solution used irrigate crops in greenhouses is lost as a drain and contaminates the groundwater. With closed production design, the drain is returned to the nutrient cycle, and a more efficient use of resources can be achieved. Within the scope of this project, a model plant will be developed in which the nutrient solution will be mixed in a closed nutrient cycle using the drain on the basis of an automatic ion-specific dosage of individual nutrient ions. It is not only intended to react to the changes in the drain posteriori, but a priori with the help of models, the expected water and nutrient uptake of the plant included in the control.

PROSIBOR - Process simulation based on plant response - Development of a sensor-based intelligent greenhouse management system

Promotion: BLE

Project partner: University Weihenstephan-Tristorf, Fa. RAM Klimacomputertechnik Herrschimg

Experimental plants: Organic gardening Watzkendorf, nursery Neber vegetables, Berglen

The aim of the project "Development of a sensor-based intelligent greenhouse management system" is to develop an analysis tool for the industry that allows producers to follow the reactions of the culture, resource savings (eg water, energy) and the resulting business consequences to one computer without having to intervene in the ongoing production process. For this, sensor-based data software is developed that simulates the production process.

At the same time, information about plant physiological processes using phytomonitors (growth, photosynthesis, transpiration, stomatal movements, etc.) is collected continuously and non-invasively. From the large variety of available information and ‘big data’, condensed information needs to be generated and generated by model-based billing indicators such as photosynthetic light utilization efficiency, photosynthetic potential utilization, photosynthetic water use efficiency, or vapour concentration difference; information with which future decision making and culture management strategies can be selected.